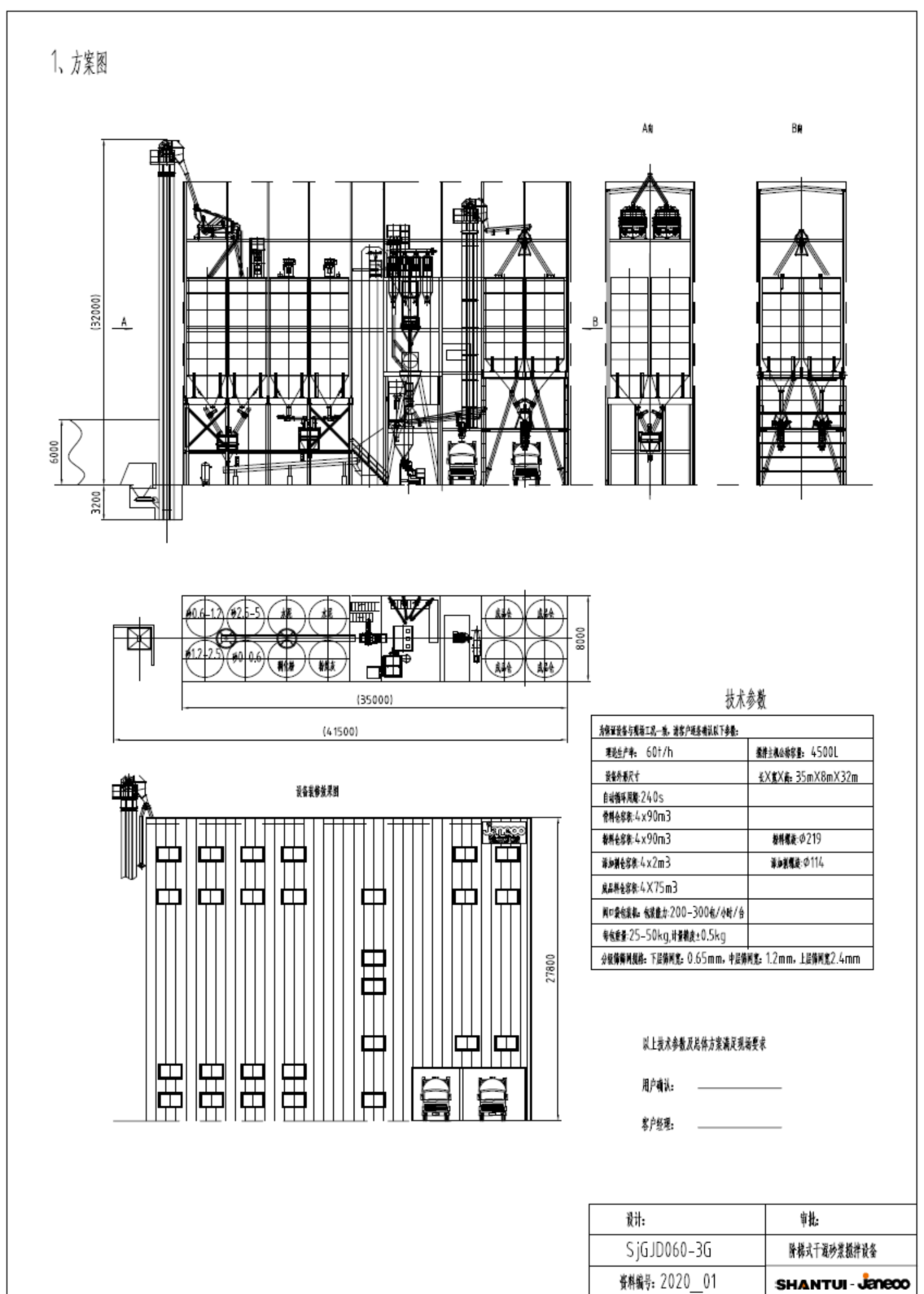

1.main specifications Theoretical productivity 60t/h Mixer SjGD4500-5B aggregates measuring accuracy±2% Cement measuring accuracy ±1% additive measuring accuracy ±0.5% Sand silo volume 4X90m3 Cement silo volume 4X90m3 Additive silo volume 4X2m3 Packing capacity 200-300bags/h/set Total power 330kW 1.Sand hoisting elevator

1.main specifications Theoretical productivity 60t/h Mixer SjGD4500-5B aggregates measuring accuracy±2% Cement measuring accuracy ±1% additive measuring accuracy ±0.5% Sand silo volume 4X90m3 Cement silo volume 4X90m3 Additive silo volume 4X2m3 Packing capacity 200-300bags/h/set Total power 330kW 1.Sand hoisting elevator | Type | TB60 |

| Hoist speed | 1.1m/s |

| Theoretical capacity | 60m3/h |

| Motor power | 15kW |

| Motor power | 2x3.6kW |

| graded layer | 3 layers |

| Volume | 90m3 |

| Diameter | 3.4m |

| Volume | 90m3 |

| Diameter | 3.4m |

| Volume | 2m3 |

| Size | 0.9x0.9m |

| Volume | 75m3 |

| Diameter | 3.4m |

| Diameter | 219mm |

| Capacity | 60t/h |

| Motor power | 5.5kW |

| type | electronic scale |

| Max value | 4000kg |

| Accuracy | ±2% |

| Mixer | SjGD4500-5B |

| Max value | 1500kg |

| Accuracy | ±1% |

| type | electronic scale |

| Max value | 150kg |

| Accuracy | ±0.5% |

| type | TB110 |

| pressure | 1.1m/s |

| capacity | 110m3/h |

| motor power | 22kW |

| Mixer | SjGD4500-5B |

| motor power | 90Kw |

| blade power | 4x5.5Kw |

| packing capacity | 200~300 bags/h/set |

| each weight | 25~50Kg |

| accuracy | ±0.5Kg |

| type | GX400 |

| capacity | 42m3/h |

| motor power | 15kW |

| type | GX400 |

| capacity | 42m3/h |

| motor power | 11kW |

| type | GX400 |

| capacity | 42m3/h |

| motor power | 11kW |

| capacity | 100t/h |

| flexible distance of discharging gate | 1200mm |

| motor power | 0.55kW |

| Filter fan power | 2.2kW |

| TB60 | TB60 |

| hoist speed | 1.1m/s |

| capacity | 60m3/h |

| motor power | 15kW |

| Main buliding filter type | HMC48 |

| power | 4Kw |

| packing filter type | HMC48 |

| power | 4Kw |

| auto | 240s |

| Standard equipment | ||||

| No. | Description | Item | Qty | Remark |

| 1 | Dry sand hoist device | 1 |

| |

| (约33m, 15 KW)elevator | 1 | |||

| platform and ladder | 1 | |||

| chute of feeding and discharging | 1 | |||

| 2 | graded screen | 1 |

| |

| 3. layers screen nets:lower:0.65mmmid:1.2mm,upper 2.4mm | 2 | |||

| chute of feeding and discharging | 1 | |||

| 3 | 砂仓除尘及出料sand silo | 1 |

| |

| discharging chute | 4 | |||

| (DN300)valve | 4 | |||

| pneumatic valve | 4 | |||

| HMC48 filter | 1 | |||

| 4 | cement and sand measuring scale | 1 |

| |

| 3000kg sand measuring scale max 3000kg | 1 | |||

| pressure sensor | 3 | |||

| (DN250)pneumatic valve | 1 | |||

| vibrator MVE60/3 | 1 | |||

| 1500kg | 1 | |||

| pressure sensor | 3 | |||

| pneumatic valve(DN250) | 1 | |||

| vibrator MVE60/3 | 1 | |||

| 5 | mixture delivery system | 1 |

| |

| screw GX500 | 1 | |||

| accessories | 1 | |||

| 6 | mixture hoist elevator | 1 |

| |

| TB110 elevator (约20m,22kw) | 1 | |||

| chute of feeding and discharging gate | 1 | |||

| 7 | additive feeding and storage tank | 1 |

| |

| additive silo(V:2m3) | 4 | |||

| rotary level meter | 4 | |||

| manual valve(DN300) | 4 | |||

| pneumatic valve(DN150) | 4 | |||

| vibrator MVE60/3 | 4 | |||

| filter system | 1 | |||

| 8 | additive measuring scale | 1 |

| |

| max value 150kg | 1 | |||

| pressure sensor | 3 | |||

| pneumatic valve(DN250) | 2 | |||

| vibrator MVE60/3 | 1 | |||

| 9 | additive hoist device | 1 |

| |

| support | 1 | |||

| rail | 1 | |||

| hoist cage | 1 | |||

| electric hoist 2000Kg | 1 | |||

| 10 | manual feeding device | 1 |

| |

| manual feeding silo | 1 | |||

| pneumatic valve(DN200) | 1 | |||

| 11 | mid-storage hopper | 1 |

| |

| hopper body | 1 | |||

| pressure sensor | 1 | |||

| pneumatic valve(DN300) | 2 | |||

| vibrator MVE60/3 | 1 | |||

| 12 | mixing system(V:4500L) | 1 |

| |

| driving device 90KW | 1 | |||

| mixing device | 1 | |||

| high speed rotary scraper 5.5KW | 4 | |||

| discharging gate | 1 | |||

| mixing tank | 1 | |||

| sample device | 1 | |||

| 13 | storage hopper | 1 |

| |

| hopper body | 1 | |||

| vibrator MVE 60/3 | 2 | |||

| impelled feeder | 1 | |||

| rotary level meter | 1 | |||

| pneumatic 4 phase valve | 1 | |||

| 14 | bulk and packing machine | 1 |

| |

| bulk machine | 1 | |||

| hopper body | 1 | |||

| rotary level meter | 2 | |||

| vibrator MVE 60/3 | 2 | |||

| double exit packing machine | 1 | |||

| belt machine (L=2500m,B=650mm,2.2kw) | 1 | |||

|

| ||||

| 15 | production hoist and delivery system | 1 |

| |

| elevator(19m,15kw) | 1 | |||

| ladder and platform | 1 | |||

| chute of feeding and discharging gate | 1 | |||

| rotary distributer | 1 | |||

| 16 | production bulk | 1 |

| |

| chute of discharge | 4 | |||

| pneumatic insert valve | 4 | |||

| pneumatic valve(DN300) | 4 | |||

| transition hopper | 1 | |||

| bulk machine | 2 | |||

| 17 | Main building filter device | 1 |

| |

| Pulse back flush filter 36m2 4KW | 1 | |||

| filter pipes | 1 | |||

| manual valve(DN150) | 2 | |||

| pneumatic valve(DN250) | 1 | |||

| 18 | packing filter device | 1 |

| |

| Pulse back flush filter 36m2 4KW | 1 | |||

| manual valve(DN150) | 1 | |||

| filter pipes | 1 | |||

| 19 | pneumatic system | 1 |

| |

| air compressor | 1 | |||

| storage tank 1m3 | 1 | |||

| storage tank 0.3m3 | 2 | |||

| main filter | 1 | |||

| dryer | 1 | |||

| joints | 1 | |||

| 20 | control system | 1 |

| |

| industrial computer | 1 | |||

| software | 1 | |||

| electric components | 1 | |||

| main frequency inverter | 1 | |||

| LED monitor | 1 | |||

| printer | 1 | |||

| Power supply | 1 | |||

| operation table | 1 | |||

| electrical carbinet | 1 | |||

| wires and cables | 1 | |||

| 21 | surveillance system | 1 |

| |

| color camera | 4 | |||

| amera lens | 4 | |||

| 19 LED monitor | 1 | |||

| insert DV | 1 | |||

| 22 | control room | 1 |

| |

| control room frame | 1 | |||

| inner and outer decoration | 1 | |||

| illumation and switch | 1 | |||

| air conditioner | 1 | |||

| 23 | Main steel structure | 1 |

| |

| chassis | 1 | |||

| ladder | 1 | |||

| support leg | 1 | |||

| Storage delivery equipment | ||||

|

|

| |||

| 24 | cement screw conveyor | φ219-2140 | 4 |

|

| 25 | 机additive screw conveyor | Ø114-2000 | 2 |

|

| 26 | 机additive screw conveyor | Ø114-1300 | 2 |

|

| 27 | production screw conveyor(before elevator) | GX400-6500 | 1 |

|

| 28 | production screw conveyor(after bulk machine and elevator) | GX400-5000 | 2 |

|

| 29 | raw material storage bin (现场制作) | 1 |

| |

| sand silo:dia 3.4m,V 90m3 | 4 | |||

| 粉仓cement silo:dia 3.4m,V 90m3 | 4 | |||

| manual valve | 4 | |||

| level meter | 8 | |||

| arch breaker | 4 | |||

| manual valve | 4 | |||

| level meter | 8 | |||

| safe valve | 4 | |||

| pulse back flush filter | 4 | |||

| steel structure support | 1 | |||

| 30 | production storage silo |

| ||

| silo:dia 3.4m,V:75m3 | 4 | |||

| arch breaker | 4 | |||

| manual valve(DN300) | 4 | |||

| rotary level meter | 8 | |||

| (1.5kw)pulse back flush filter | 1 | |||

| steel structure support | 1 | |||

| 31 | decoration | 1 |

| |

| decoration 2500m2,(0.5mm) | 1 | |||

| body frame, windows and doors | 1 | |||